FRIENDSHIP SYSTEMS Advanced Design and Modelling Software for Pumps, Valves and Related Components

FRIENDSHIP SYSTEMS is a leading provider of innovative software and services that have been specially developed to optimise the shape and design of industrial pumps, valves and components using highly automated computational fluid dynamics (CFD) analysis processes.

Our advanced CAESES software enables engineers to conduct precise, CFD-driven design studies to achieve the most effective fluid dynamic behaviour for their products in their respective applications.

Automated pump and valve design software for the water industry

FRIENDSHIP SYSTEMS’ CAESES software delivers flexible and completely automated computer-aided design (CAD) modelling and flow simulation processes, providing production personnel with the ability to perform comprehensive design studies without the need for manual interaction.

CAESES’ capabilities allow engineers to investigate large sets of design candidates using powerful workstations and high-performance computer (HPC) clusters in an extremely short space of time, for example overnight or over the weekend.

We regularly collaborate with all major CFD vendors and our solutions can be integrated with open-source CFD packages when required. Compatible systems include FINE / Turbo, ANSYS CFX, PumpLinx, STAR-CCM+ and OpenFOAM, as well as a variety of proprietary in-house tools.

CAESES is relied upon by industry-leading companies across the global water sector to improve the shape of their complex flow-exposed components and assist in the creation of reliable, highly competitive products.

Efficient pump design and optimisation solutions for water applications

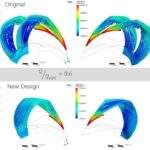

CAESES has been carefully developed to facilitate fast and comprehensive pump design using CFD-driven shape optimisation solutions to ensure high-performance and reliability.

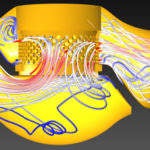

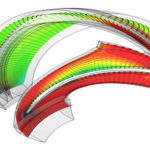

Our software system generates quick, precise and flexible impeller and volute geometries during the variation stage, which can be fully automated for added convenience during shape optimisation processes.

CAESES’ robust design capabilities, combined with the expert knowledge of the operating engineer, enable the creation of a comprehensive range of pump systems to address a wide selection of industrial requirements.

CAESES is integrated with specialist impeller and meridional channel modelling techniques to provide additional calculation and engineering assistance, while typical theta and beta distributions can be applied to camber-based design approaches when required.

Customisable modelling software for industrial casings and components

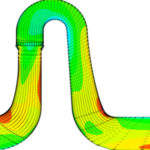

CAESES’ versatile camber and thickness modelling processes have been designed to be as flexible and open as possible. In contrast to ‘black box’ systems with limited adaptive capabilities, all CAESES’ design parameters can be completely customised in accordance with clients’ individual specifications to ensure maximum compatibility.

The pump geometries generated by our software typically contain fixed identifiers such as unique colour settings in order to automate the meshing procedure prior to commencing CFD analyses.

These geometries are closed and clean so that the meshing works effectively without pre-processing, which also removes the need for manual user interaction to significantly accelerate the entire design process.

A number of prominent engineering companies such as KSB, EBARA and Hitachi leverage FRIENDSHIP SYSTEMS’ pioneering technology during the development of their pumps, casings and related components to achieve consistently high-quality results.

Variable geometry and CFD design solutions for the water sector

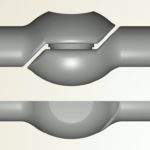

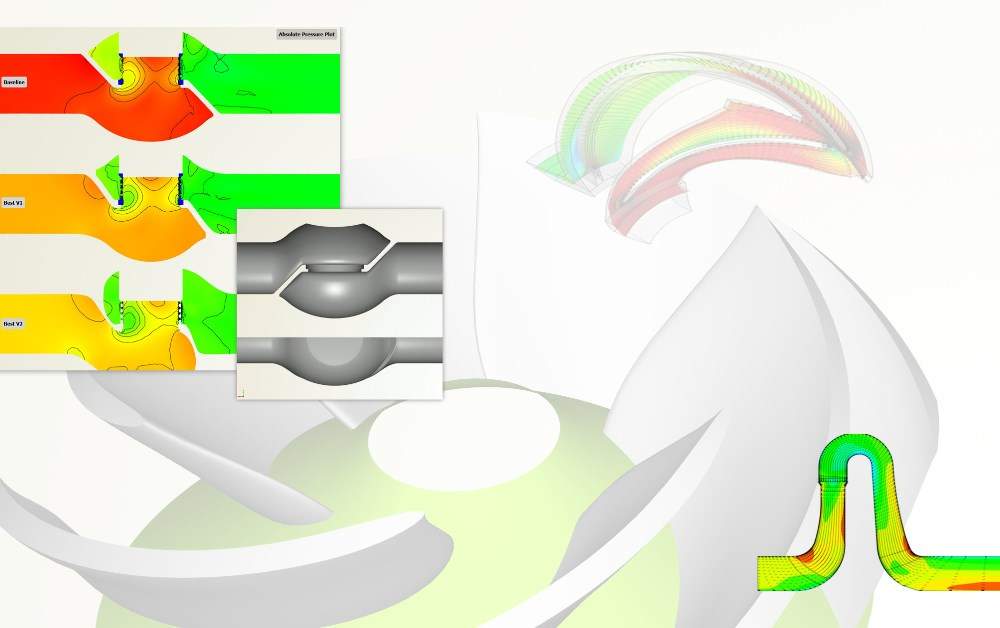

FRIENDSHIP SYSTEMS’ CAESES solution is equipped with highly efficient surface modelling capabilities that can be easily linked to integrated optimisation strategies in order to create the most efficient valve geometries and flow characteristics in the shortest possible timeframe.

CAESES provides operators with in-depth design knowledge and the solution is able to identify optimal valve shapes for a given application through its in-built post-processing capabilities. The software allows users to investigate hundreds or even thousands of design candidates in conjunction with CFD simulation data to deliver highly accurate calculations.

Our cutting-edge solutions can be used to design and optimise the flow characteristics of any type of valve and the company is able to provide expert assistance during the set-up and installation of the software to ensure consistently reliable operation.

CAESES also enables users to develop and improve an all-inclusive array of nozzles, diffusers and perforation patterns using automated CFD and variable geometry assessments. For example, German firm ARCA successfully optimised the shape of a large control valve by using a combination of CAESES and Autodesk Simulation CFD as part of a fully automated design process.

Products and Services

Video

Related Projects

Press Release

Friendship Systems has announced that the new CAESES has been released. Even though this is formally a maintenance release, we have added a few new capabilities based on user requests from the last couple of months.

Read moreFRIENDSHIP SYSTEMS, along with the developer of Optimus and id8, Noesis Solutions, has launched a direct integration with CAESES.

Read moreFRIENDSHIP SYSTEMS AG continues to take steps to reduce energy consumption and emissions by supporting customers to improve their products.

Read moreDespite frequently being seen as the cheap workboxes of the global dirty ore and coal trade, bulk carriers must comply with a growing number of efficiency, safety and environmental regulations.

Read moreCompetition in the European market of offshore wind OMS (Operation, Maintenance and Service) is expected to grow significantly in upcoming years, with shipowners continuously looking to lower costs, increase efficiency and accelerate profitability of vessels.

Read moreA new version of FRIENDSHIP SYSTEMS AG geometry modelling and optimisation software, CAESES® 4.4, has been released

Read more