Aqualyng Seawater or Brackish-Water RO Desalination Plants

Aqualyng are a company devoted to the production of desalination plants based on the principle of reverse osmosis. We provide solutions to the problem of shortage of fresh water by seawater desalination at a very competitive cost and world-record lowest energy consumption rates. We also manufacture a range of high quality and compact modules of seawater or brackish-water RO desalination plants with the latest technology.

REVERSE OSMOSIS DESALINATION PLANTS

Our purpose is fresh water production. We produce five different standard sizes, but we are also flexible to adapt our designs to your needs.

The standard modules are:

- 500m³/day

- 1,000m³/day

- 2,000m³/day

- 5,000m³/day

- 10,000m³/day

SAND FILTRATION AND FINER BAG FILTRATION

These standard modular units enable us to build-up or tailor make reverse osmosis systems to almost any size. Other equipment we supply includes:

- Sand filtration or more complex treatment unit process

- Extra and finer bag filtration

- Chemical injection

- Disinfection

- Membrane cleaning skid

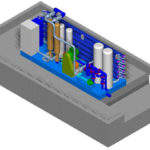

RO-500STD-AQUALYNG

A very compact solution. It is design to be installed inside a container and is environmental friendly with high efficiency and low energy consumption.

This standard unit comprises:

- Pre-treatment of feed water by a step of fine-bag filters rated to 5 micron nominal size (back-wash system included)

- Aqualyng’s energy recovery system: “The Recuperator” with surge tanks and hydraulic-controlled valves

- High Pressure Pump (HPP)

- Reverse Osmosis (RO) skid

- Remineralisation unit

RO-1000STD-AQUALYNG

A very compact and efficient system. Includes all our standard equipments with optimal surface use at only 60m². It produces high quality fresh water at incredibly low energy consumption rates.

This standard unit comprises:

- Pre-treatment of feed water by a step of fine-bag filters rated to 5 micron nominal size (back-wash system included)

- Aqualyng’s energy recovery system: “The Recuperator” with surge tanks and hydraulic-controlled valves.

- High Pressure Pump (HPP)

- Reverse Osmosis (RO) skid

- Remineralisation unit

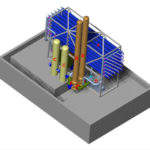

RO-2000STD-AQUALYNG

It produces 2,000m³/day of fresh water of the highest quality. Robust and compact conception, the optimal size for small desalination plants is 65m².

This standard unit comprises:

- Pre-treatment of feed water by a step of fine-bag filters rated to 5 micron nominal size (back-wash system included)

- Aqualyng’s energy recovery system: “The Recuperator” with surge tanks and hydraulic-controlled valves

- High Pressure Pump (HPP)

- Reverse Osmosis (RO) skid

- Remineralisation unit

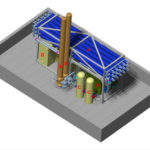

RO-5000STD-AQUALYNG

Has a modular design and is the starting point for our larger plants. Has a high quality and production capacity from a single module with only 136m² of building required.

This standard unit comprises:

- Pre-treatment of feed water by a step of fine-bag filters rated to 5 micron nominal size (back-wash system included)

- Aqualyng’s energy recovery system: “The Recuperator” with surge tanks and hydraulic-controlled valves

- High Pressure Pump (HPP)

- Reverse Osmosis (RO) skid

- Remineralisation unit

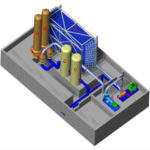

RO-10 000STD-AQUALYNG

This is our largest modular unit. Classifies as a medium capacity RO desalination plant. Has a compact design and automatic operation and surveillance.

This standard unit comprises:

- Pre-treatment of feed water by a step of fine-bag filters rated to 5 micron nominal size (back-wash system included)

- Aqualyng’s energy recovery system: “The Recuperator” with surge tanks and hydraulic-controlled valves

- High Pressure Pump (HPP)

- Reverse Osmosis (RO) skid

- Remineralisation unit

Products and Services

Video

White Papers

Related Projects

Fujairah 1 Independent Water and Power Plant Expansion

Monterey Peninsula Water Supply Project (MPWSP), California

Campo de Dalías Reverse Osmosis Desalination Plant

Charles E. Meyer Desalination Plant Reactivation, California

Tuaspring Desalination and Integrated Power Plant

Press Release

Regional Offices

Lyng Gruppen

Vanvikan

7125

Other

Norway